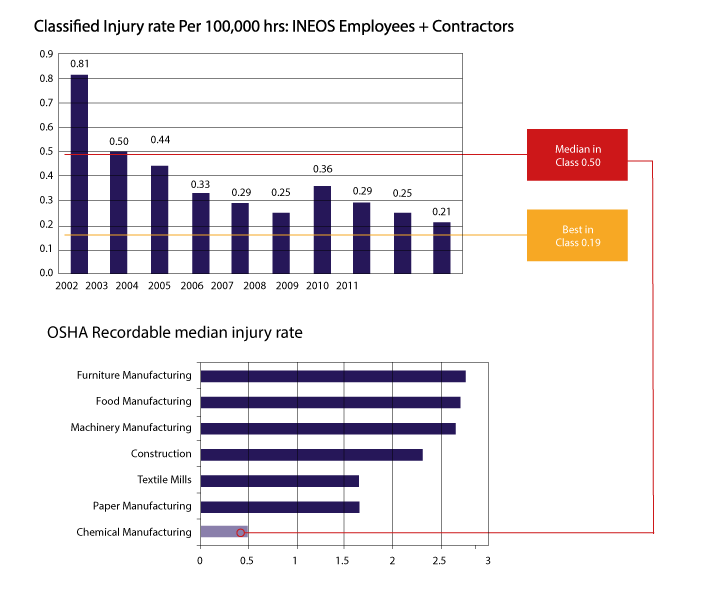

Last year INEOS’ safety record improved from 0.25 classified injuries per 100,000 hours to 0.21. It was the fourth year in a row that the company had been able to show continuous improvement. Steve Yee, Business Safety Health & Environment Manager, takes a look at the company’s approach.

Communication works for those who work at it; so said British composer John Powell who has written the scores to more than 50 films.

And in terms of its communication of safety, it’s an area in which INEOS excels. Some would say it’s become somewhat of an obsession, but with exceptionally good reason.

INEOS operates in a hazardous business with potential to cause harm if control is not of the highest standards. This is why no job will ever be seen on its sites as so important that anyone’s wellbeing should be put at risk. And ‘anyone’ includes those living or working close to INEOS’ plants.

Steve Yee is the man responsible for collating the Group’s safety reports.

“If there’s an incident on any one of our sites, I will know about it,” he said.

He often compares INEOS’ safety performance with similar chemical companies around the world.

“Our ultimate goal is not to harm people, so understanding the statistics is only part of the solution to help us to achieve this goal. Understanding how to keep the chemicals inside the process is key to our business.”

“What the figures do tell us, though, is that we can never become complacent, improvements are always achievable. It takes a long time to improve the safety performance and a short time for it to fall back. We can never take our eye off the ball for a second.”

Last year, INEOS’ safety record improved from 0.25 classified injuries per 100,000 hours to 0.21. It was the fourth year in a row that the company had been able to show continuous improvement and it reflected the hard work and commitment that exists at every level to prevent accidents.

Steve said, looking at human factors at work – and identifying how we can work on them to improve was a major focus of last year.

“Most of our injuries are not chemically related,” he said. “Most are slips, trips or falls.”

“Our performance is very good but we can never become complacent. If we are to continuously improve we must all critically assess what we do, avoid taking short-cuts and do the right thing even if it takes a little longer. It is about changing behaviours so that we all become increasingly more careful.”

Key principles that will set the standard across the company – 10 based on human factors which we have named behavioural safety and 10 on process safety – these principles are all based on learning from incidents or ‘near miss’ safety alerts.

Process safety

-

The asset operating manager is responsible for its overall integrity

-

The asset engineers are responsible for maintaining the asset and protective systems’ integrity

-

The responsibilities in the organisation for defining and maintaining the correct operating envelopes must be clea

-

Operating procedures and envelopes must be observed. Deviations must be reported and investigated

-

Any changes must be properly risk assessed and subjected to MOC procedures

-

Process hazards are systematically identified, risk assessed, reviewed and managed

-

All assets must be subject to periodic inspection designed to ensure their integrity and the reliability of their protective systems

-

Operations must always place the safe operation or shutdown of the asset ahead of production

-

When in doubt the asset must always be taken to its safest state

-

We have emergency plans based on assessed risks which are regularly tested

Human factors

-

We believe all incidents and injuries can be prevented

-

Everyone’s first responsibility is to ensure they work safely

-

Everyone has the duty to stop work if they feel the situation is unsafe

-

The expectations and standards are the same for everyone on the site

-

Rules and procedures must be observed and respected

-

We should look out for each other’s safety and unsafe situations

-

All injuries and incidents / near misses must be reported and investigated

-

Risk assessment must be carried out prior to, during and on completion of work

-

All team leaders have a special responsibility for promoting and upholding these principles

-

We must always work within the limit of our competency and training

Changing our behaviours, though, isn’t as easy as it sounds.

“It can take years to change it but you can lose it within six months because people will do what they have always done,” he said. “People are human.”

At INEOS, we expect the same high standards for everyone, whether they are employees, contractors or visitors. Not unlike the rest of the chemical industry we see a different incidence compared with employees. Over the years we have seen improvement, but we still wish to improve upon that.

Like all Chemical majors, INEOS tracks and reports more than is required by local laws.

“We see each ‘near miss’ as a warning sign, and a source of valuable information that we can learn from, whether it is in INEOS or in other companies,” said Steve.

“We continuously improve our systems with the help of ‘near miss’ reports. By tracking, monitoring and sharing these across the Group, information from all ‘near misses’ helps to prevent actual incidents from happening. It is pretty obvious really. Waiting for accidents to happen is just not an option for us.”

“Each incident that is serious or has content that is good for learning is reported as a SHE Alert and the findings are then issued to all businesses within the Group.”

“These SHE (safety, health and environmental) Alerts could potentially help to avert similar problems at another site.”

Improving Safety is a commitment that starts with INEOS Capital, through the Boards of each business and throughout the organisation.

There is a chain of command through each business that ensures, by the end of the process, that every single employee will have been kept in the loop.

“Each INEOS business is clearly accountable for its performance,” said Steve.

“A lot of big companies operate in a different way to us. Other Chemical Companies may take a lot of direction and auditing from a central SHE organisation. My belief is that if you do that then you take away the responsibility and accountability from the people that can make the improvements. That won’t work.”

So, as INEOS seeks to continue its improving trend and better 2011 performance, it is rolling out one of its most ambitious projects to date.

To drive improvements in safety performance, Tony Traynor, the INEOS Group Operations Director led an initiative of the INEOS process safety management team to develop two sets of 10 key principles that will set the standard across the company – 10 based on human factors which we have named behavioural safety and 10 on process safety – these principles are all based on actual incidents or ‘near miss’ SHE Alerts.

“They are based on best practice from across INEOS and from other chemical companies from around the world. We have taken a massive amount of information and consolidated it into something that people will understand and that will help us to go beyond the excellent performance we have seen this year.”

When asked if 20 is too many, Steve is pretty clear. “I don’t think so. They are what they are. These key principles come from the knowledge we have acquired over the years, we believe they cover all incidents. Had someone followed these principles then all of the incidents we have seen in the past few years, be they INEOS or other companies could have been prevented. So I believe it is the right number.”

Part of the problem for the chemical industry is, though, the perception of the public. It is just the way it is, hich is why we work hard to make sure that our local communities understand us and how our safety and environmental performance is continuously improving.

“Most chemical incidents, large or small, make the headlines. Yet the chemical sector safety performance is far better than many other industries. That is a fact.”

“Looking at the injury rates across many other manufacturing industries the chemicals sector is by far one of the best performers. Don’t get me wrong, there is always room for improvement. For me, even a single injury across the whole sector is an injury that could have been prevented.”

“I know I can sleep at night because each of the Business Boards monitor the safety systems, procedures, people and emergency responses are all designed (and continuously checked) to keep the risk levels low. If there is a deviation from that I would see it in the safety reporting.”