Overview

An FPS waiver is required when:

- there is an expectation that the customer’s pipeline liquids will not meet their quality specification; or

- when the customer's pipeline liquids have breached their quality specification

Failure to complete and submit a request for an FPS waiver in a timely fashion may, in particular, if it causes a safety issue, result in the customers’ production being restricted or shut-in.

FPS customers must not deliver Pipeline Liquids into FPS that does not meet their TPA quality specification unless they have an approved waiver from FPS. INEOS will invoice customers for all costs incurred in assessing FPS waiver requests and in handling the off-specification pipeline liquids.

Waiver Requests: fpswaiver@ineos.com

Waiver categories

Category 1 waivers

All waivers that pose a low to medium level of risk to FPS fall into Category 1. The impact and likelihood of risks associated with Category 1 waivers form the basis of the risk charges described under the Waiver fees section. The risk posed by Category 1 waivers is relatively well understood and a majority of the waivers are covered by this category. Typical chemical products that are not covered by a Category 1 waiver are: Ethanol, Sealants, Gels, Gases (e.g. N2). FPS will inform the customer if the chemical product in question would require a Category 2 waiver.

Category 1 waiver process follows the following steps:![fps-flow1_Page_1 (1).jpg fps-flow1_Page_1 (1).jpg]() NOTE: Once a waiver is granted no changes can be made to the dates & volumes indicated in the granted form without closing out the existing waiver and raising a new request. INEOS has sole discretion as to whether or not it grants a waiver request. The waivers inbox is monitored 24/7 and there is an on call engineer for any genuinely urgent requests. However, INEOS does not guarantee timely review of the waivers submitted outside the normal notification window.

NOTE: Once a waiver is granted no changes can be made to the dates & volumes indicated in the granted form without closing out the existing waiver and raising a new request. INEOS has sole discretion as to whether or not it grants a waiver request. The waivers inbox is monitored 24/7 and there is an on call engineer for any genuinely urgent requests. However, INEOS does not guarantee timely review of the waivers submitted outside the normal notification window.

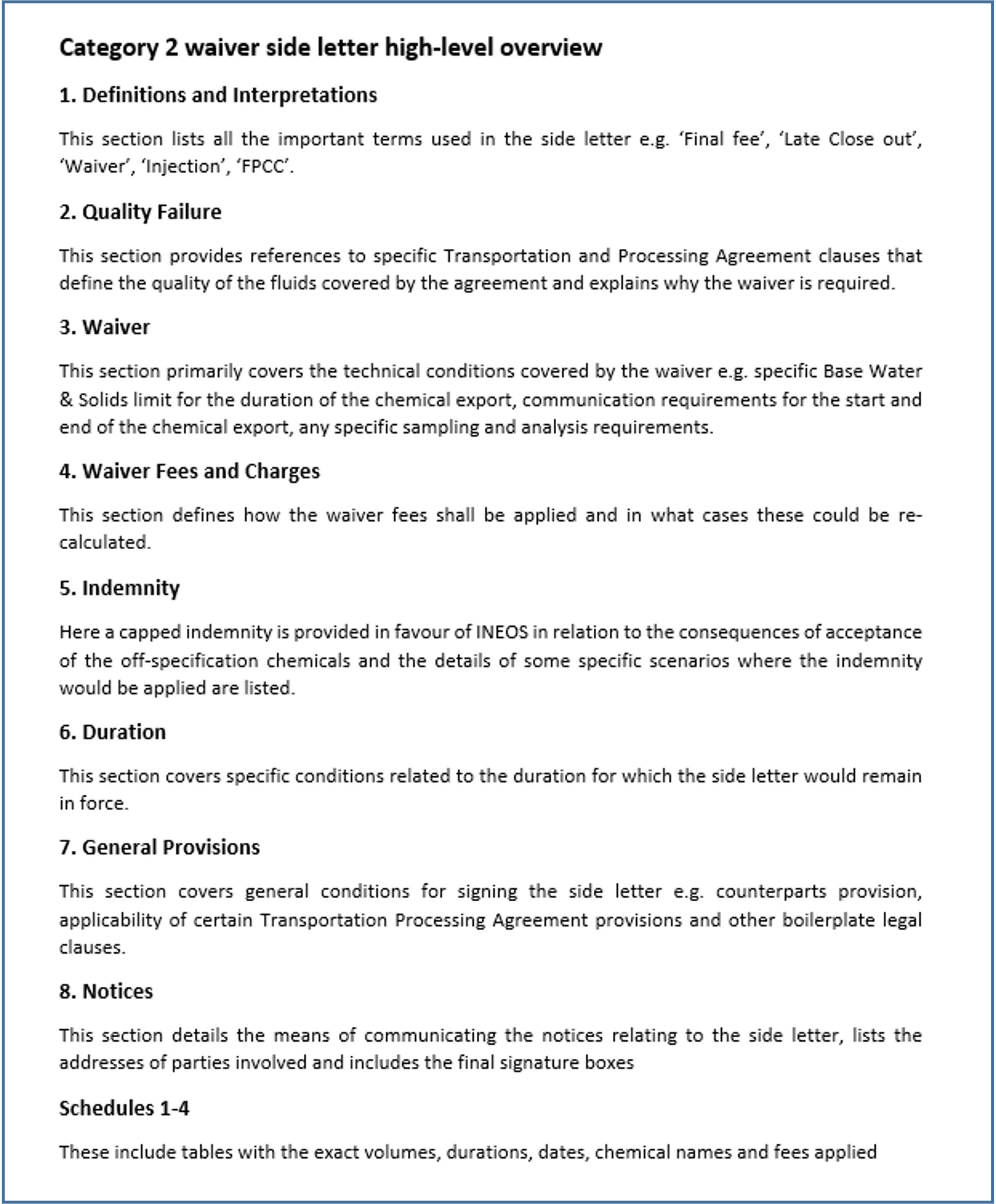

Category 2 waivers

Waivers that pose a high risk to FPS operation fall into Category 2. High risk categorisation may be driven by previous experience of FPS with certain chemicals resulting in incidents or by the lack of experience leading to uncertainty in terms of the potential impact. Sealants and gels are examples of Category 2 chemical products due to the risk of blockages on Unity and Kinneil caused by products not fully breaking down prior to reaching FPS facilities. Blockages could lead to safety incidents (blocked instrument tubing or drain pipework), production restrictions and shut down (blocked inlet filters at the terminal) or result in additional maintenance requirements.

Another typical Category 2 waiver example is Ethanol. It can lead to poor gas product quality, resulting in extensive flaring and loss of gas product revenue. It is also a chemical with a high COD and BOD level, and could lead to breaching the water effluent specification at Kinneil.

Category 2 waiver might also cover more commonly used chemicals, such as methanol, if FPS have concerns about the entrant platform managing to achieve a certain partitioning factor to ensure the volume of methanol exported into FPS remains within the terminal limit.

The issue of a Category 2 waiver could take up to 3 months. The outline of Category 2 process is below. A high-level summary of a Category 2 Waiver Side letter is also presented further down on this page.

Due to the risk of the long-term corrosion, seawater use is covered by a Seawater waiver side letter, which is a simplified version of the Category 2 waiver - no indemnity is included (see the high-level side letter summary below).

NOTE: The decision whether the chemical product falls under Category 1 or Category 2 is at the sole discretion of Ineos FPS.

![fps-flow1_Page_2 (1).jpg fps-flow1_Page_2 (1).jpg]()

![cat-2-waiver.png cat-2-waiver.png]()

Waiver types based on the chemical product

Standard Waivers

Standard waivers cover the following chemicals:

- Methanol

- Glycol

- Water

- Biocide

- Contaminants (e.g. H2S)

- Ethanol

These chemicals are classified as standard due to the frequency of which they are used within FPS. The risks posed by these chemicals are well understood and special trackers are used for determining the exact arrival times at Kinneil. The list of the data to be provided by the customers for these chemicals is short: volume, injection date, duration, partitioning factor. To request a standard waiver a customer needs to fill in a request form as per Waiver forms section and email it to FPS waivers inbox no later than 72 hours in advance of the expected injection date. Waivers submitted with less than 72 hour notice may still be reviewed and processed, however this cannot be guaranteed. See Waiver Fees section for short notice waiver fees.

Note that a chemical being determined as standard does not exclude it from falling under Category 2 process if other factors are present (i.e. the risk might be well understood but still high). All other chemicals are classified as ‘Non-standard’ waivers.

The assessment process of standard waivers is based on the forecasted flowrates and estimated arrival times of the chemicals at Kinneil versus the expected loading and available capacity on the corresponding dates of arrival. Due to the uncertainty associated with production forecast for more than 2 weeks ahead of any chemical injection date, standard waivers can only be granted maximum 2 weeks before the proposed injection date. Customers are welcome to request waivers more than 2 weeks in advance, however, the granted form will only be issued no more than 14 days before the requested injection date.

Summary of the risks associated with standard chemicals

Methanol

Methanol partitions into both oil and water phase within exported crude oil and impacts both the gas quality and the effluent water quality at Kinneil.

Methanol has a significant impact on the six Kinneil molecular sieve beds that absorb water and H2S from the propane product stream, as methanol is absorbed by the beds in preference to water and H2S. This reduces the molecular sieve’s absorption capacity which leads to the production of off-specification propane. Once methanol has been absorbed by the bed it cannot be totally regenerated; this significantly reduces the molecular sieve bed’s lifespan which increases the frequency that the bed has to be changed out.

Methanol is an alcohol and has a strong affinity to water. BOD is one of the criteria Kinneil effluent water has a specification for. Methanol that arrives at Kinneil partitioned into the water phase ends up in Kinneil’s effluent stream, resulting in significant contribution towards daily BOD loading.

Due to the risks described above, agreeing a methanol partitioning factor (percentage of methanol injected upstream on each customer platform that gets exported into FPS) is very important to ensure methanol waivers are adequately assessed. Partitioning factor must be modelled for each field and formally reviewed and agreed by Ineos FPS (note that FPS safety factor is applied to any partitioning factor obtained by computer modelling). Once agreed, methanol partitioning factors are entered into FPS waivers system and revisited only if there are any significant process changes on the customers’ side.

Glycol

Glycol is an alcohol and primarily partitions into water. BOD is one of the criteria Kinneil effluent water has a specification for. Glycol that arrives at Kinneil within water phase ends up in Kinneil’s effluent stream, resulting in significant contribution towards daily BOD loading. Any glycol waiver request requires partitioning factor calculation to be included as part of the waiver request.

Water

FPS has limited capacity for handling water and has been receiving an increasing number of requests from customers for excess water handling services, which have to be managed carefully within system limits. Incompatible produced waters can present a significant risk to FPS operations, either through scaling or inefficient separation.

Biocide

Only tetrakis (hydroxymethyl)phosphonium sulfate (THPS) based biocide is classified as standard biocide and is the preferred biocide for the use within FPS. Any other biocide request is classified as a non-standard waiver and must follow non-standard waivers assessment process. THPS based biocide impacts effluent water toxicity level at Dalmeny tank farm. Prior to water tanks rundown effluent water must be below THPS level limit of 5ppm.

Contaminants e.g. H2S & CO2

Crude oil contaminant waivers are reviewed and risk assessed on the case by case basis, as these often have a direct impact on the pipeline and terminal integrity. FPS has safe operating limits that cannot be breached, therefore any contaminant concentrations exceeding those agreed in individual TPAs are carefully reviewed by both the waivers and integrity teams.

Ethanol

Ethanol (IMS) partitions into both oil and water phase within exported crude oil and impacts both the gas quality and the effluent water quality at Kinneil.

Ethanol has a significant impact on the butane specification leading to the loss of product and flaring.

Ethanol is an alcohol and has a strong affinity to water. BOD is one of the criteria Kinneil effluent water has a specification for. Ethanol that arrives at Kinneil partitioned into the water phase ends up in Kinneil’s effluent stream, resulting in significant contribution towards daily BOD loading.

Due to a high number of flaring events in the past being caused by ethanol arrival at Kinneil, all ethanol waivers fall under Category 2.

Non-standard Waivers

All chemicals that are not classified as Standard chemicals are covered by Non-standard waivers. These include corrosion inhibitors, scale inhibitors, H2S scavengers, foamers, anti-foams, wax inhibitors, clarifiers and other chemical products. The assessment process for non-standard waivers is more complex, as it involves assessment against 40 different criteria primarily based on Kinneil effluent specification limits. For all non-standard waiver requests, the customer must supply MSDS and CEFAS sheets in addition to the data covering the injection date and volume, partitioning factor calculation, toxicity, BOD, COD, pH, density, solubility and presence of any contaminants listed in the form. To request a Non-standard waiver a customer needs to fill in a request form as per Waiver forms section and email it together with the MSDS and CEFAS sheets to FPS waivers inbox no later than 1 month in advance of the expected injection date. Even if some data is still missing it is very important to inform FPS about the intent of using a non-standard chemical as early as possible. This is to ensure that there is enough time to complete an adequate assessment and feedback any clarifications and changes required to the customer with the minimal impact on the planned scope. The final waiver form must be submitted at least 72 hours prior to the proposed injection time. There is a high chance of the waiver not being granted in time if a non-standard waiver request is submitted with less than 72 hour notice. See Waiver Fees section for short notice waiver fees.

Summary of the risks associated with Non-standard chemicals

Due to a large range of chemicals that are covered by non-standard waivers there is a number of risks that are taken into account in the review process. Chemicals that are water soluble impact the effluent water specification, including the pH, BOD/COD levels, toxicity levels and contaminant levels. Even if the chemical is insoluble in water it could still impact the effluent water specification if oil in water limit is breached and some of the chemical ends up in the water stream. Surfactants can impact oil/water separation, dyes can impact the colour of the effluent water, corrosion inhibitors can cause compatibility issues with FPS corrosion inhibitor. Certain non-standard chemicals that pose a significant risk to FPS operation, such as gels and sealants, for example, are covered by Category 2 waiver process.

Waiver types based on injection frequency and duration

Ad-hoc Waivers

Ad-hoc waivers cover injection of any chemical for a maximum duration of 1 month required on ad-hoc (i.e. non-continuous) basis. All standard waivers are covered by Ad-hoc waivers. Application process involves submission of the individual waiver request form per chemical, described in Waiver forms section. For Non-standard waivers the customer can choose between having a monthly ad-hoc waiver or an annual waiver covering the injection of the chemical, as long as the injection frequency meets the criteria for annual waivers.

Annual Waivers

Chemicals that are injected on a continuous basis throughout the year are covered by the Annual waivers process. The frequency required for injection to be classified as continuous is anything between daily and every 2 weeks. Standard chemicals cannot be covered by the Annual waivers process as injection of these chemicals is assessed based on the daily flowrate and daily loading and capacity availability at Kinneil and Dalmeny. The exception to this is Biocide, which can now be offered as an annual waiver.

For 2024 the annual waivers timings are changing.

Annual waiver requests should be submitted by the 28th of Feb of each year covering injection over the year ahead. Granted waiver forms will be issued by the 31st March. For example, annual waiver requests covering injection between 1st April 2024 and 28th March 2025 should be submitted by the 28th February 2024 and would subsequently be granted by the 31st March 2024. Please see Waiver Fees section for Annual waiver charges.

Please see Waiver Fees section for Annual waiver charges.

Breach Notification

If customers discover that they have exceeded their TPA quality specification then they must complete a breach notification form (see Waiver forms section) and send it to FPS waiver team immediately. The same process must be followed if customers exceed the volume indicated in their granted waiver form for any chemical product. All breaches must be reported within 24 hours of the chemical injection time. Early reporting of the breach is essential, which should include a full explanation as to why the breach occurred and the mitigation plan that will be put in place to prevent future occurrences. Please see Waiver Fees section for the charges associated with the late breach notification.

Waiver Close Outs

Any granted ad-hoc waiver requires submission of a corresponding close out form by the customer within 24 hours of completion of the chemical export. For example, if the export of the chemical started at 00:00 on the 1st Jan 2021 and continued for 30 hours (till 06:00 on the 2nd Jan), the close out form must be submitted by 06:00 on the 3rd Jan the latest. The close out form must contain the actual volume of the chemical injected, the start date and time of the chemical export into FPS and the duration of the chemical export. (See Waiver Forms section for more detail) Timely close out submission is important to ensure the impact of the chemicals on Kinneil is recorded and traceable and any unused capacity booked in the system is made available to other users as soon as possible. Waivers will be invoiced based on the granted waiver form volumes if no close out details are submitted prior to the issue of the corresponding monthly invoices (see Invoicing section for detail). Submission of waiver close outs outside 24 hour period or no close out submission is subject to the late close out fee (see Waiver Fees section for detail).

Any granted annual waiver requires quarterly reporting of the actual chemicals volume injected. Quarterly annual waiver reporting must be submitted by the 28th of April for Q1 (total volume of each chemical injected between 1st January and 31st March), 28th July for Q2 (total volume of each chemical injected between 1st April and 30th June), 28th October for Q3 (total volume of each chemical injected between 1st July and 30th September) and 28th January for Q4 (total volume of each chemical injected between 1st October and 31st December). Granted Annual Waivers form must be used for quarterly volumes reporting. Submission of the quarterly reporting outside the 28 day window or no quarterly reporting submission is subject to the late annual waiver reporting fee (see Waiver Fees section for detail).

Category 1 Waiver Fees

Short Notice fee

Waivers requested less than 72 hours before they are required will incur the following fees in addition to the regular waiver charge.

| Methanol & Water ad-hoc waivers |

All other ad-hoc waivers |

|

£186.65

|

£1,200.00

|

Late Close Out fee

Ad-hoc waivers that are not closed out within 24 hours of exporting the off-specification pipeline liquids will incur a fee per waiver in addition to the regular waiver charge.

The fee is required to ensure that system capacity is not sterilised which could then prevent other users from essential routine or emergency operational activities.

|

NUMBER OF LATE CLOSE OUTS IN YEAR

|

METHANOL & WATER AD-HOC WAIVERS

|

ALL OTHER AD-HOC WAIVERS

|

|

0-10

|

£186.65

|

£622.15

|

|

11-20

|

£1,866.46

|

£6,221.53

|

|

20+

|

£18,664.60

|

£62,215.34

|

The fees are assessed on a yearly basis; the total number of late close outs is reset to zero for each field at the start of each new calendar year.

Annual waivers that are not covered by a timely quarterly volumes reporting will incur a fee of £1,244.31 per chemical per delayed quarterly volumes reporting.

Breach fee

The following revised breach notification fees will be charged in addition to the regular waiver charge based on the breach notification time. Notifying INEOS within 24 hours off the start of export into FPS will incur a smaller fee than notification outside the 24 hour window.

| Within 24 hours window |

Outside 24 hour window |

| £4,355.07 |

£8,710.15 |

Chemical volumes injected under annual waivers are reported by customers on a quarterly basis. Any reported volumes in excess of the granted quarterly volume will be charged with a breach fee (either the <24hrs fee above if quarterly reporting data is provided on time, or the >24h fee above if reporting data is late).

Contaminant Waivers (e.g. H2S) fees

All contaminant waivers will be charged a fixed fee of £3,110.77 per waiver.

Note that short notice, late close out and breach fees still apply to contaminant waiver charges.

Admin fee

This fee covers the costs incurred by FPS in administering each waiver and is based on the manhours spent assessing and processing each waiver.

| Standard ad-hoc waiver (exc. contaminants) |

Non-standard ad-hoc waiver |

Annual waiver |

| £311.08 |

£808.80 |

£559.94 |

OPEX fee

This fee covers the costs incurred by FPS in processing the fluids containing the chemical products.

| Non-standard ad-hoc waiver |

Water waiver |

Methanol waiver |

Biocide waiver |

Glycol waiver |

Annual waiver |

| £18.67/waiver |

£1.244/bbl |

£1,990.89/m3 |

£1,244.31/m3 |

£248.86/m3 |

£130.65/waiver |

FPS margin

A charge of 10% of the combined admin plus OPEX charges will be applied to all waivers except contaminant waivers.

Duration fee

This fee covers the increased risk to FPS that comes with reduced certainty over timing of injections. The wider the window, the higher the charge. The charges will be as follows:

| Duration of waiver |

Duration fee |

| 0-48 hours |

£0 |

| 49-168 hours (1 week) |

£124.43 |

| 169-744 hours (1 month) |

£622.15 |

| Annual waiver |

£0 |

Risk fee

This fee covers everyday risk to FPS operations and its regulatory compliance from typical changes to offshore operations, assuming operators abide by the terms of their granted waivers. This charge explicitly does not cover risk to system operation whenever the terms of the waiver are breached.

Risk fees for standard waivers

| Chemical product |

Current FPS daily limit |

Contribution towards FPS Daily Limit |

| |

<10% |

<10%-50% |

50%-100% |

| Methanol |

1.8 m3 |

£2,488.61 |

£4,977.23 |

£7,465.84 |

| Glycol |

1 m3 |

£497.72 |

£2,488.61 |

£4,977.23 |

| Biocide |

126 litres (110 litres accounting for annual waivers) Fixed risk fee of £1,244.31 |

| Water |

7000 bbl |

No risk fee |

Risk fees for non-standard waivers

For each of the 40 assessment criteria based on FPS PPC, effluent trading agreement and company accepted limits, FPS will assess the contribution of the granted waiver towards the FPS daily limits, and charge as follows:

| |

Contribution towards FPS Daily Limit |

| |

<10% (Risk score 1) |

10%-50% (Risk score 2) |

50%-100% (Risk score 3) |

>100% (Risk score 4) |

| Each FPS criteria |

£37.33 |

£136.87 |

£311.08 |

£1,244.31 |

If no data is provided for any of the criteria listed on the revised waiver request form, the pricing mechanism will default to >100% of FPS daily limit for that specific criteria.

For the chemicals that are insoluble in water, each criteria will by default be assessed as ‘<10%’. For the chemicals that are classified as PLONOR under CEFAS classification, no risk fees will be charged.

Note that it is unlikely that FPS would grant an ad-hoc waiver that contributed >100% of FPS daily limit.

Annual waiver fees

FPS will calculate Annual waiver charges following the same process as for ad-hoc waivers. The risk is increased due to higher number of injections but this is partially offset due to consistency of injections. For each of the 40 assessment criteria based on FPS PPC, effluent trading agreement and company accepted limits, FPS will assess the contribution of the granted waiver towards the FPS daily limits, and charge as follows:

| |

|

Contribution towards FPS Daily Limit |

| |

|

<10% |

10%-50% |

50%-100% |

>100% |

| Each FPS criteria |

£261.30 |

£958.12 |

£2,177.54 |

£8,710.15 |

Note that it is unlikely that FPS would grant an annual waiver that contributed >100% of FPS daily limit.

Category 2 Waiver Fees

Category 2 waiver fees are calculated on a case by case basis driven by the man-hours spent agreeing the waiver conditions, operational costs incurred by FPS in processing the waived fluids, the risk level posed to FPS operations.

Invoicing

FPS will invoice customers for the appropriate waiver fee 4-6 weeks in arrears. The invoice will state the quantity and types of waiver that the customer has applied for during the relevant month.

Escalation

The waiver charges outlined here will be revised periodically whenever FPS carries out a detailed cost review or if there are any significant operational/regulatory changes. Waiver charges will otherwise be escalated annually per calendar year using the most current monthly RPI (Retail Price Index) data available from the ONS website

(https://www.ons.gov.uk/economy/inflationandpriceindices/timeseries/chaw/mm23).

Waiver Process

Customers must apply for a waiver before exporting contaminants into FPS. Customers must apply for the waiver at least 72 hours before it is required. For methanol, water, H2S scavenger and frequently used chemicals we will accept waivers requests no earlier than 2 weeks prior to the commencement date; this is because before that period there is too much uncertainty about system throughput.

For new production chemical waivers, e.g. not previously approved, then a longer notice period, of approximately 2 months, is required in order for INEOS to carry out the right level of due diligence before we are able to make a decision whether or not to approve the waiver request. INEOS will not put FPS at risk by approving waivers without carrying out the full due diligence required.

INEOS acknowledges that there are occasions, such as plant trips, when short notice waivers are required and we will endeavour to accept these short notice requests but we make no guarantees.

INEOS will monitor waiver request notice periods and we will contact those customers who make short notice waiver requests, other than for plant trips. Failure to comply with the required notice period may result in your waiver request being delayed and/ or a penalty administrative charge being applied.

Waiver requests will be assessed on a first come first served basis.

Approval

INEOS has sole discretion as to whether or not it grants a waiver request. If INEOS does elect to grant a waiver it will only do so in consideration of the relevant customer paying INEOS’s administration costs and an estimate of the incremental costs incurred by INEOS to transport and process the off-specification liquids (see Waiver Fees section).

INEOS’s ability to approve a waiver will depend on the capacity available in FPS and on the use of that capacity by other customers at the time. If INEOS is unable to approve the waiver request we may suggest an alternative date or duration that could be accommodated.

Duration of Waiver

Normally waivers are granted based on hours of use during each 24 hour period. We accept that there may be some uncertainty as to when the contaminant will be injected and subsequently delivered into FPS and we will allow, wherever possible, some flexibly by granting a waiver for a longer period of time than is actually needed. We will not, however, tolerate customers sterilising capacity in FPS due to lack of planning. If we believe that the requested duration is excessive we will reject the waiver request and ask the customer to resubmit for a shorter duration.

Approved Waivers

If INEOS approves a waiver request we will e-mail an approved waiver form back to the requestor. The customer must strictly comply with the terms of the waiver, which will be set out in the accompanying e-mail. Failure to comply with the terms may result in the waiver being revoked.

If there are any changes to the details of the waiver requested then the customers must contact the FPS waiver team (fpswaiver@ineos.com) immediately and request their advice. The customer must not export contaminants into FPS if to do so would be outwith the terms of the approved waiver.

NOTE: Once a waiver is granted no changes can be made to the dates & volumes indicated in the granted form without closing out the existing waiver and raising a new request. INEOS has sole discretion as to whether or not it grants a waiver request. The waivers inbox is monitored 24/7 and there is an on call engineer for any genuinely urgent requests. However, INEOS does not guarantee timely review of the waivers submitted outside the normal notification window.

NOTE: Once a waiver is granted no changes can be made to the dates & volumes indicated in the granted form without closing out the existing waiver and raising a new request. INEOS has sole discretion as to whether or not it grants a waiver request. The waivers inbox is monitored 24/7 and there is an on call engineer for any genuinely urgent requests. However, INEOS does not guarantee timely review of the waivers submitted outside the normal notification window.