Durasyn Polyalphaolefin

Below you will find information on Durasyn® products.

Overview

Documentation for all products is accessible via our "VIEW OUR PRODUCT RANGE" link. For any additional technical information, please e-mail us at oligomersinfo@ineos.com or request a sample of our products via our "REQUEST A SAMPLE” link below.

VIEW OUR PRODUCT RANGE Request a sample

INEOS Oligomers is the world's largest merchant marketer of polyalphaolefins (PAO) synthetic fluids marketed under the trade name Durasyn.

INEOS has Durasyn PAO production plants in LaPorte (Texas, USA), Chocolate Bayou (Texas, USA) and Feluy (Belgium). All sites are integrated with INEOS’ Linear Alpha Olefin (LAO) product line, which provides the feedstock for the production of Durasyn fluids.

The INEOS polyalphaolefin business has a global presence, with regional commercial teams located throughout the U.S., Europe and Asia. We employ a highly experienced technical group, an experienced and professional network of local sales staff and local distributors to assure true global reach.

Durasyn polyalphaolefin synthetic fluids have greater film thickness at high temperatures than comparable Group I, Group II or Group III mineral oils. This results in superior high temperature protection for equipment lubricated with polyalphaolefin-based synthetic lubricants. Lubricants containing Durasyn polyalphaolefin also achieve full lubrication more quickly at low temperatures than comparable mineral oil-based lubricants due to their superior low temperature viscometrics and lower pour points. This is an important performance benefit given that a high percentage of component wear occurs during cold equipment start-up.

PAO-based synthetic lubricants are highly shear stable and are generally acknowledged to have better thermal / oxidative stability than comparable mineral oil-based lubricants. Improved oxidation resistance yields lower viscosity increase in service and reduces the deposit and varnish forming tendencies of lubricants.

Durasyn PAOs are used in a wide variety of industrial and automotive applications including passenger car motor oils, wind turbine lubricants, heavy-duty diesel engine oils, fiber optic cable compounds, transmission fluids, compressor oils, hydraulic oils and gear oils. Durasyn PAOs are also authorized for use as components of food grade lubricants and are registered with the National Sanitary Foundation (NSF) under H1 and HX-1 classifications.

Performance Features

- Exceptional low temperature viscometrics

- Excellent thermal, oxidative and hydrolytic stability

- High Viscosity Indices (VI)

- Some grades possess high biodegradability

- Colorless and odorless

- No sulfur, nitrogen or aromatics

- Non-toxic, non-corrosive

- Uniform (engineered) molecular structure

The main Durasyn PAO products are:

1-Decene (C10) Based

Metallocene High Viscosity 1-decene (C10) based

Durasyn 162, 164, 166, 168, 170

Durasyn 174I, 176, 180R, 180I, 185

Performance benefits of Durasyn PAO-based lubricants:

Film Thickness

Relative to mineral oil-derived lubricants, PAO synthetic lubricants have greater film thickness at high temperatures. This results in superior high temperature protection for equipment lubricated with PAO-based synthetics.

Low Temperature Fluidity

PAO-based synthetic lubricants achieve full lubrication more quickly at low temperatures than comparable mineral oil-based lubricants due to their inherently lower pour points and low-temperature viscosities. This is an important performance benefit given that a high percentage of component wear occurs during cold equipment start-up.

Shear Stability

Synthetic lubricants formulated with polyalphaolefins are highly shear stable. When oils shear out of grade, usually due to chain scission of polymeric viscosity index improvers, it results in oils with significantly lower viscosities, which may not be able to prevent metal-metal contact and attendant wear. PAO containing formulations show little shear loss under demanding conditions and maintain their ability to protect against wear.

Oxidative Stability

Synthetic lubricants formulated with polyalphaolefins are generally acknowledged to have better oxidative stability than comparable Group I, Group II or Group III mineral oil-based lubricants. Improved oxidation resistance yields lower viscosity increase in service and less deposit formation and varnish build-up; in other words, the internal surfaces of rotating equipment are cleaner. It is common for synthetic lubricants to provide 5 to 10 times longer life than mineral oil-based fluids.

High Temperature Stability

When exposed to the oxidizing effect of air, polyalphaolefins are less prone to form sludge and deposits than mineral-based lubricants. Sludge and deposits can restrict oil flow and may interfere with heat removal in rotating equipment. The inherent high temperature stability of PAOs can significantly decrease rotating equipment failures, decrease equipment maintenance and allow oil change intervals to be extended.

High Viscosity Index

Polyalphaolefins exhibit relatively constant viscosity with increasing temperature. The parameter used to measure a fluid's ability to resist viscosity change with increasing temperature is viscosity index (VI). Thus, PAOs have high viscosity indices compared to many petroleum derived fluids. The high inherent viscosity indices of PAOs can reduce the requirement for shear prone high molecular weight viscosity modifiers.

Low Friction

PAO-based synthetic lubricants are superior to mineral-based oils in their ability to reduce friction due to a combination of many of the features described above. Several studies have documented significant reductions in energy consumption when PAO-based synthetic lubricants are used in a variety of transportation and industrial rotating equipment applications.

Biodegradability

Unlike mineral oils, low viscosity polyalphaolefin synthetic fluids (especially 2 and 4mm2/s fluids) are inherently biodegradable. PAO fluids are also considered to be non-toxic and non-irritating to mammals. In environmentally sensitive applications, such as drilling muds or hydraulic fluids for earth moving equipment, PAO fluids have advantages over conventional mineral oils and some natural esters because of their unique combination of physical, chemical, and environmental properties.

Durasyn Low Viscosity (Low Vis) Polyalphaolefins

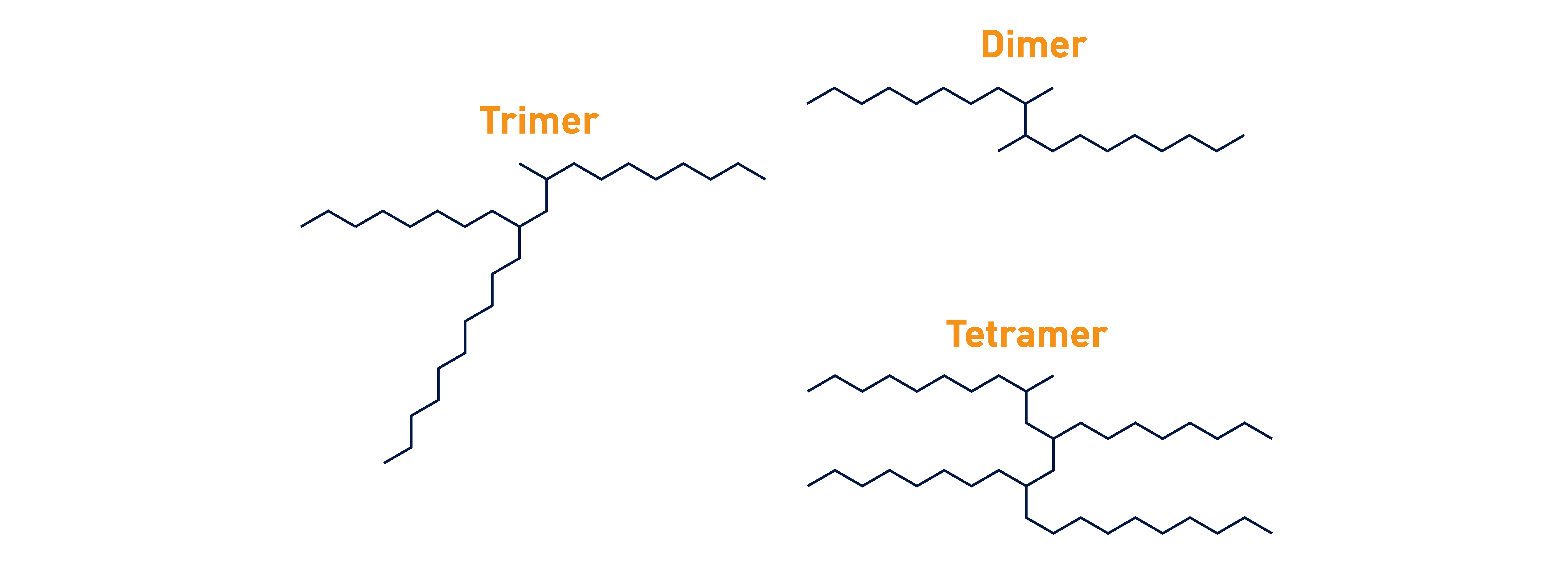

Durasyn polyalphaolefins (PAO) are produced by oligomerizing alpha olefins (1-olefins) in the presence of an acidic catalyst to a mixture of olefin dimers, trimers, tetramers and higher oligomers (*approximate structures shown below). In the final step, these oligomers are hydrogenated to produce a fully saturated hydrocarbon mixture. These hydrogenated oligomers are additionally fractionated to produce our Durasyn low viscosity products with viscosities from 2 mm2/s at 100°C to 10 mm2/s at 100°C.

*approximate structures of oligomers present in polyalphaolefin

*approximate structures of oligomers present in polyalphaolefin

Durasyn High Viscosity (Hi Vis) Polyalphaolefins

INEOS Oligomers has completed start-up of a new world scale high viscosity (hi vis) mPAO (metallocene polyalphaolefin) plant. This new unit has a nameplate capacity of twenty thousand metric tons per annum. The new plant will continue to utilize our proprietary catalyst technology that was first developed on the pilot scale and then optimized in our semi-works unit.

INEOS remains committed to the use of high purity 1-decene as the feedstock for our high viscosity PAOs. In comparison to conventional high viscosity PAOs, our decene-based metallocene products have a number of superior attributes such as higher viscosity indices, lower pour points and lower Brookfield viscosities.

HIGH VISCOSITY DURASYN POLYALPHAOLEFIN

Durasyn high viscosity polyalphaolefins are shear stable viscosity modifiers/enhancers designed for use in the formulation of high quality transportation and industrial lubricants. Key application areas include wind turbine oils, multi-grade gear oils, greases, compressor oils, marine and stationary engine oils and passenger car/ heavy duty motor oils.

Durasyn hi vis mPAOs offer excellent thickening efficiency and superior low temperature performance when compared to conventional high viscosity polyalphaolefin or polybutene thickened oils. In addition, Durasyn hi vis PAOs have low volatility and excellent shear stability, so lubricants can be formulated that will remain in-grade during severe service.

Durasyn high viscosity metallocene polyalphaolefins are available to commercial lubricant formulators and blenders in five grades: Durasyn 174I, Durasyn 176, Durasyn 180R, Durasyn 180I and Durasyn 185.

- Durasyn 185 is a “mPAO150” that provides the most thickening of the Durasyn Metallocene polyalphaolefins.

- Durasyn 180I is a “mPAO135” with excellent thickening efficiency at 40°C.

- Durasyn 180R is a “mPAO100” that matches the 100°C viscosity specification range of conventional high viscosity PAOs.

- Durasyn 176 is a "mPAO65" with excellent thickening efficiency at 40°C.

- Durasyn 174I is a “mPAO50” which has more thickening efficiency than conventional “PAO40”.